Submersible Pump

AQR Series Catalog

AQR Series

SAMJIN submersible aquarator model AQR Series has functions of aerator and agitator with high efficiency, durability, reliability and economical effect developed by applying optimized design concept of submersible axial pump, submersible aerator and submersible mixer. This aquarator can be used for aeration of general tanks and agitation of raw water control tanks and anaerobic tanks for biological phosphate elimination. High quality and reliability are proven and guaranteed through rigid quality control programs, the latest manufacturing technology, long manufacturing experience and long life operation of these products.

Features

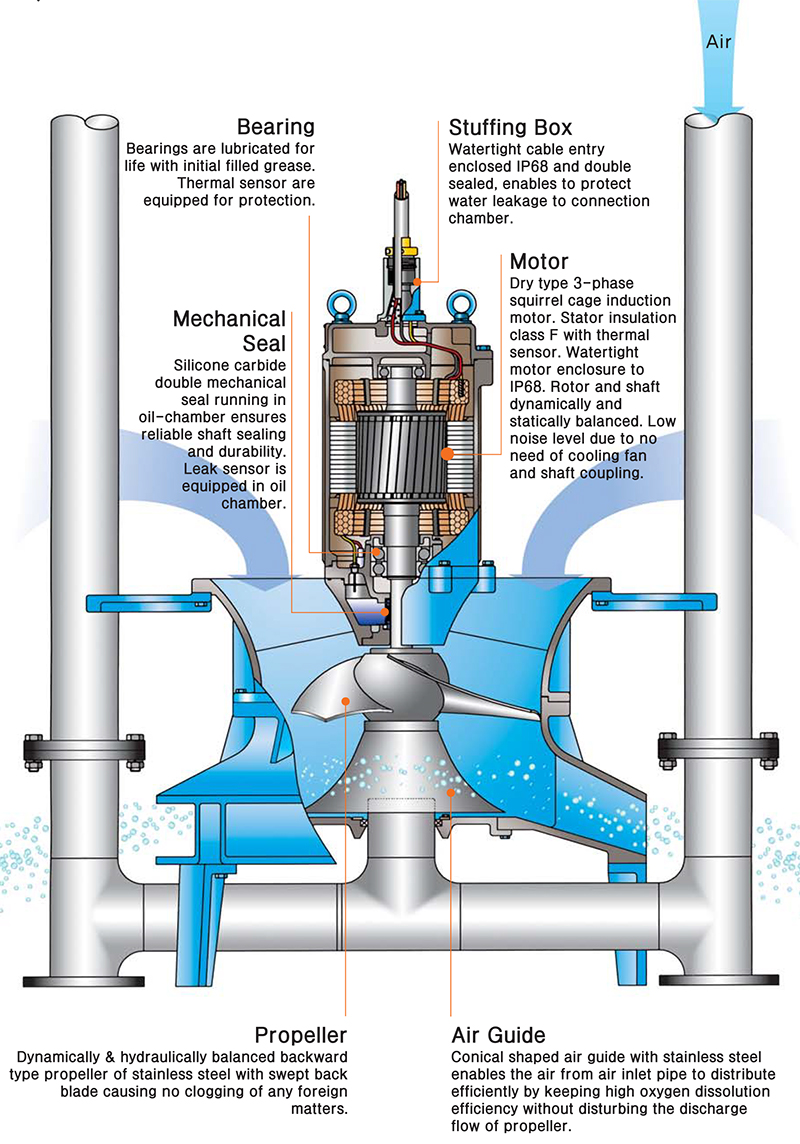

- Excellent oxygen dissolution efficiency

- Air emitted through air pipe flows into the water around the casing and mixed with water efficiently by the air/liquid collision. Accordingly excellent oxygen dissolution effect can be attained by means of convection/agitation effect due to air-liquid mixing at the outlet port and high oxygen transfer effect due to micro bubble formation.

- Strong agitating force

- Strong agitation force can be achieved by the optimum designed propeller which enables much more capacity of water mixed with air and discharges the mixed water with air to the outlet port with less power. The structure of propeller is so designed that sludge in the raw water can be passed through the propeller easily. Propeller is made of stainless steel by precise finishing and dynamic balancing, thus maintains long life operation without performance deterioration.

- Easy modification of application either aeration or agitation

- Easy selection of application either for the purpose of aeration or for the purpose of agitation. Aeration for aerobic treatment or agitation for anaerobic treatment can be selected as wanted by simply opening or closing the air control valve.

- Easy control of oxygen supply volume

- Necessary oxygen supply volume corresponding to the fluctuation of sewage volume can be attained by adjusting the air inlet control valve.

- Easy adaptability to the existing aeration tank

- The aquarator can be installed into the existing aeration tanks regardless of tank’s shape, round type, rectangular type or square type without modifications of tank.

- Easy installation and raising for check

- Easy installation and raising for check can be carried out due to no requirement of fixing anchor bolts of the aquarator on the basin floor.

Uses

Aeration and agitation for sewage, water and sludge treatmentPreliminary and main aeration in the commuting plantFish farming and live stock framing

Technical Specifications

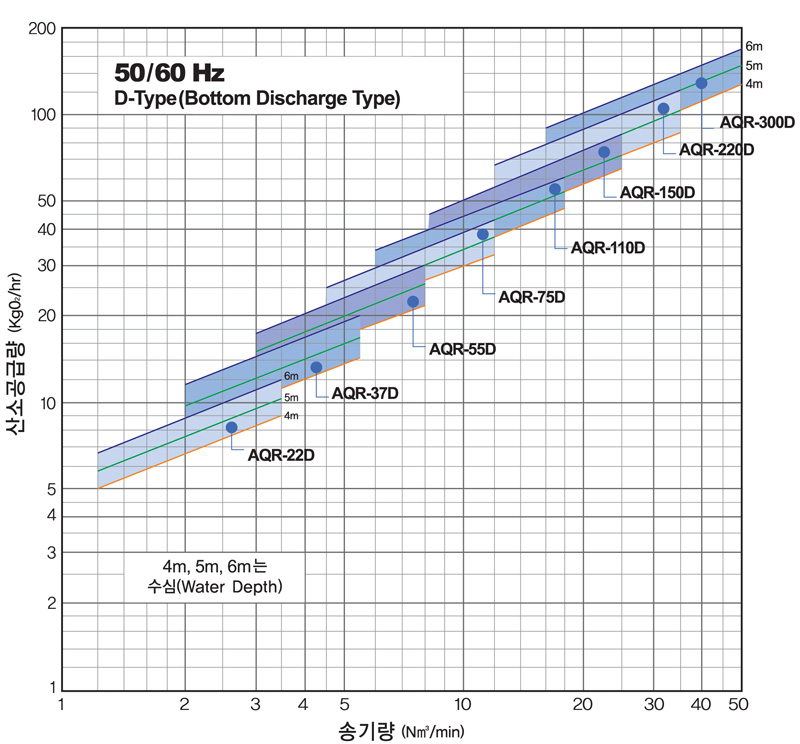

D-Type Performance Curves (Bottom Discharge Type)

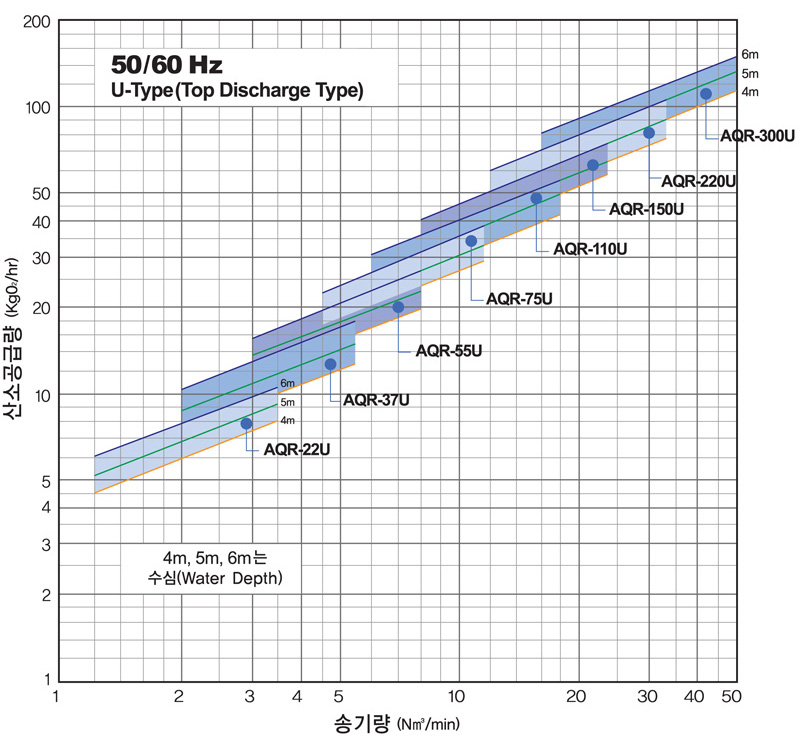

U-Type Performance Curves (Top Discharge Type)

D-Type Specification (Bottom Discharge Type)

| Model Mode |

Output (Kw) |

Air Emission Volume Range (N㎥/min) |

at Water Depth (5m) |

Max.Agitating Capacity (㎥) |

Max. Floor Space (㎥) |

Max. Pit Length (㎥) |

Min Circulation Current Volume (㎥/min) |

Req'd Pneumatic Pressure (mmAq) |

|

|---|---|---|---|---|---|---|---|---|---|

| Air Emission Volume Range (N㎥/min) |

Oxygen Supply Cap. (KgO2/hr) |

||||||||

| AQR-22D | 2.2 | 1.2~3.5 | 2.2 | 8.1 | 430 | 75 | 12 | 15 | Water Depth+150 |

| AQR-37D | 3.7 | 2.0~5.5 | 3.6 | 13.8 | 740 | 116 | 14 | 23 | Water Depth+150 |

| AQR-55D | 5.5 | 3.0~8.0 | 6.0 | 21.5 | 1100 | 184 | 18 | 35 | Water Depth+200 |

| AQR-75D | 7.5 | 4.5~12.0 | 9.0 | 32.5 | 1500 | 250 | 22 | 50 | Water Depth+200 |

| AQR-110D | 11 | 6.0~18.0 | 13.0 | 45.5 | 2200 | 390 | 25 | 65 | Water Depth+250 |

| AQR-150D | 15 | 9.0~25.0 | 20.0 | 65.0 | 2800 | 470 | 31 | 83 | Water Depth+250 |

| AQR-220D | 22 | 12.0~35.0 | 26.0 | 92.0 | 4000 | 650 | 35 | 95 | Water Depth+250 |

| AQR-300D | 30 | 16.0~50.0 | 36.0 | 125.0 | 5500 | 920 | 42 | 110 | Water Depth+250 |

Power sorce : 3Phase-50/60Hz-200/220/380/400/440/460/480V

U-Type Specification (Top Discharge Type)

| Model Mode |

Output (Kw) |

Air Emission Volume Range (N㎥/min) |

at Water Depth (5m) |

Max.Agitating Capacity (㎥) |

Max. Floor Space (㎥) |

Max. Pit Length (㎥) |

Min Circulation Current Volume (㎥/min) |

Req'd Pneumatic Pressure (mmAq) |

|

|---|---|---|---|---|---|---|---|---|---|

| Air Emission Volume Range (N㎥/min) |

Oxygen Supply Cap. (KgO2/hr) |

||||||||

| AQR-22U | 2.2 | 1.2~3.5 | 2.2 | 7.8 | 360 | 60 | 10 | 14 | Water Depth+150 |

| AQR-37U | 3.7 | 2.0~5.5 | 3.6 | 12.6 | 620 | 105 | 12 | 21 | Water Depth+150 |

| AQR-55U | 5.5 | 3.0~8.0 | 6.0 | 20.6 | 920 | 154 | 15 | 33 | Water Depth+200 |

| AQR-75U | 7.5 | 4.5~12.0 | 9.0 | 31.0 | 1250 | 210 | 20 | 45 | Water Depth+200 |

| AQR-11U | 11 | 6.0~18.0 | 13.0 | 42.5 | 1850 | 310 | 23 | 62 | Water Depth+200 |

| AQR-150U | 15 | 9.0~25.0 | 20.0 | 60.5 | 2500 | 415 | 27 | 82 | Water Depth+250 |

| AQR-22U | 22 | 12.0~35.0 | 26.0 | 85.3 | 3600 | 600 | 33 | 94 | Water Depth+250 |

| AQR-300U | 30 | 16.0~50.0 | 36.0 | 118.2 | 5000 | 835 | 40 | 108 | Water Depth+250 |

Power sorce : 3Phase-50/60Hz-200/220/380/400/440/460/480V

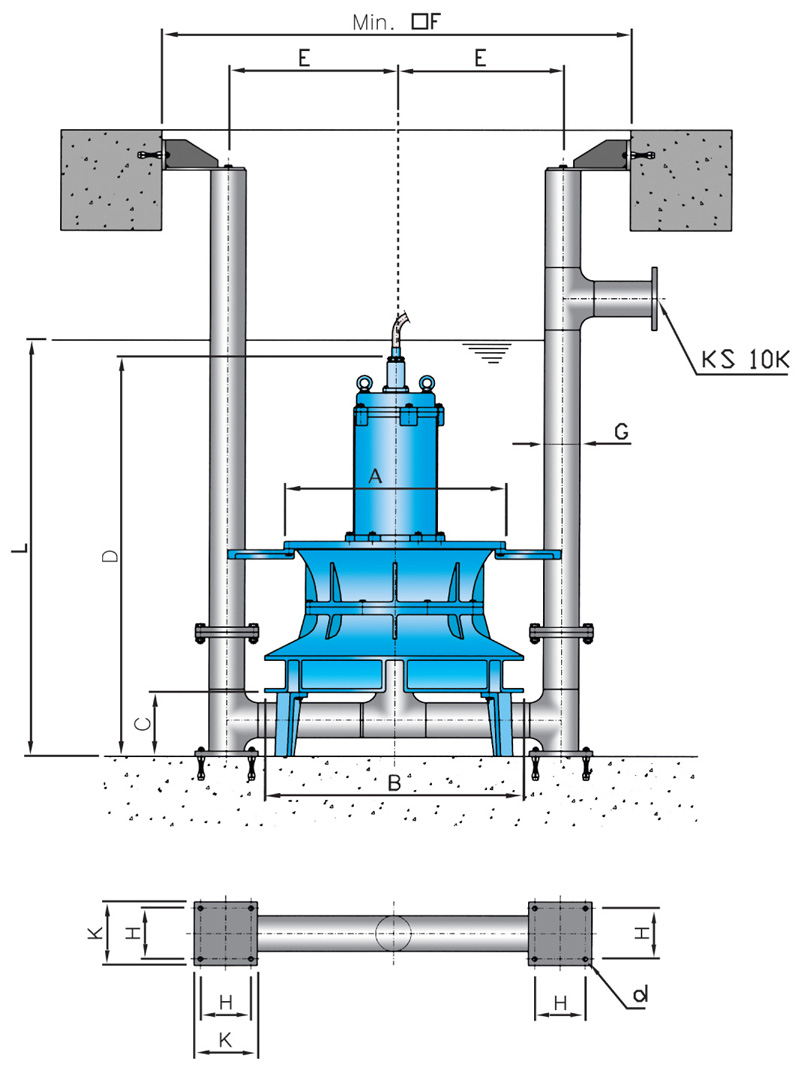

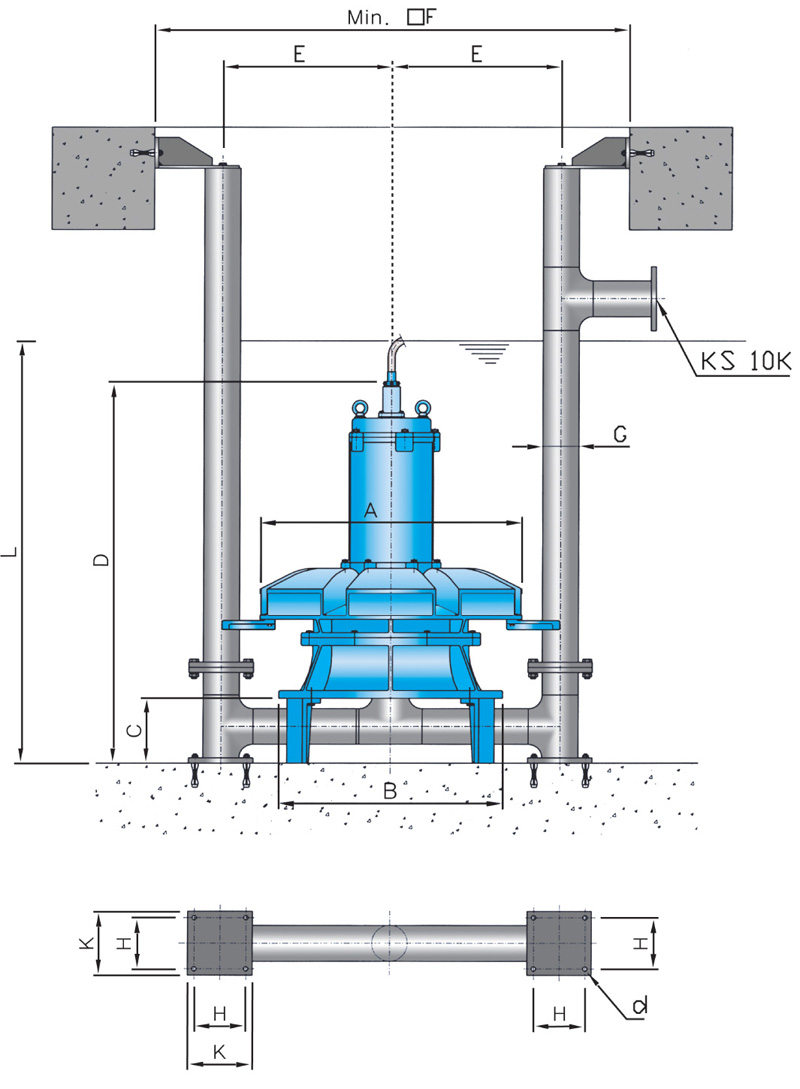

Outline Dimensions

D-Type

U-Type

D-Type (Bottom Discharge Type)

| Model | A | B | C | D | E | F | G | H | K | L | D |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AQR-22D | 627 | 670 | 151 | 1096 | 430 | 1050 | 65A | 150 | 200 | 1200 | 14 |

| AQR-37D | 627 | 740 | 170 | 1120 | 460 | 1150 | 80A | 150 | 200 | 1200 | 14 |

| AQR-55D | 872 | 890 | 230 | 1539 | 560 | 1350 | 100A | 200 | 250 | 1600 | 16 |

| AQR-75D | 872 | 1020 | 255 | 1543 | 660 | 1600 | 125A | 200 | 250 | 1600 | 16 |

| AQR-110D | 872 | 1300 | 290 | 1678 | 800 | 1850 | 150A | 200 | 250 | 1800 | 16 |

| AQR-150D | 1466 | 1590 | 290 | 1990 | 950 | 2150 | 150A | 250 | 300 | 2100 | 18 |

| AQR-220D | 1466 | 2100 | 395 | 2198 | 1230 | 2760 | 200A | 250 | 300 | 2200 | 18 |

| AQR-300D | 1466 | 2600 | 435 | 2326 | 1570 | 3500 | 250A | 250 | 300 | 2500 | 18 |

U-Type (Top Discharge Type)

| Model | A | B | C | D | E | F | G | H | K | L | D |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AQR-22U | 680 | 630 | 151 | 1096 | 430 | 1050 | 65A | 150 | 200 | 1200 | 14 |

| AQR-37U | 750 | 630 | 170 | 1120 | 460 | 1150 | 80A | 150 | 200 | 1200 | 14 |

| AQR-55U | 900 | 880 | 230 | 1539 | 560 | 1350 | 100A | 200 | 250 | 1600 | 16 |

| AQR-75U | 1100 | 880 | 255 | 1543 | 660 | 1600 | 125A | 200 | 250 | 1600 | 16 |

| AQR-110U | 1300 | 880 | 290 | 1678 | 800 | 1850 | 150A | 200 | 250 | 1800 | 16 |

| AQR-150U | 1600 | 1500 | 290 | 1990 | 950 | 2150 | 150A | 250 | 300 | 2100 | 18 |

| AQR-220U | 2100 | 1500 | 395 | 2198 | 1230 | 2760 | 200A | 250 | 300 | 2200 | 18 |

| AQR-300U | 2600 | 1500 | 435 | 2326 | 1570 | 3500 | 250A | 250 | 300 | 2500 | 18 |

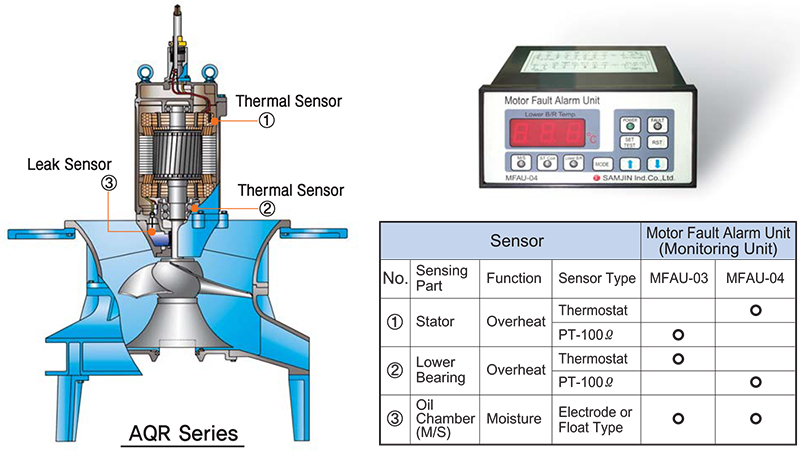

Safety protection device

Safety protection devices consist of sensors equipped in submersible motor and motor fault alarm unit (monitoring unit) to be connected to sensors are classified in to thermal sensors and leak sensors(moisture failure sensor). In case of abnormal temperature rise in the motor stator coil and in the lower bearings and in case of moisture ingress into the oil chamber due to mechanical seal failure, thermal sensors and leak sensors automatically detect respective temperature rise and moisture ingress faults and these faults are indicated on the motor fault alarm unit(monitoring unit) and at the same time the output signal is transmitted and the output contact interlocked with MCC enables to stop the pump operation to protect motor from additional damage.

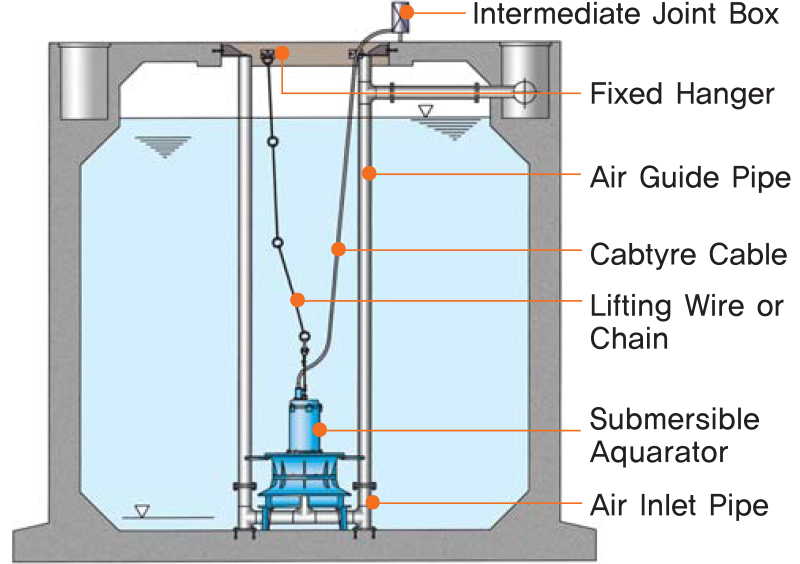

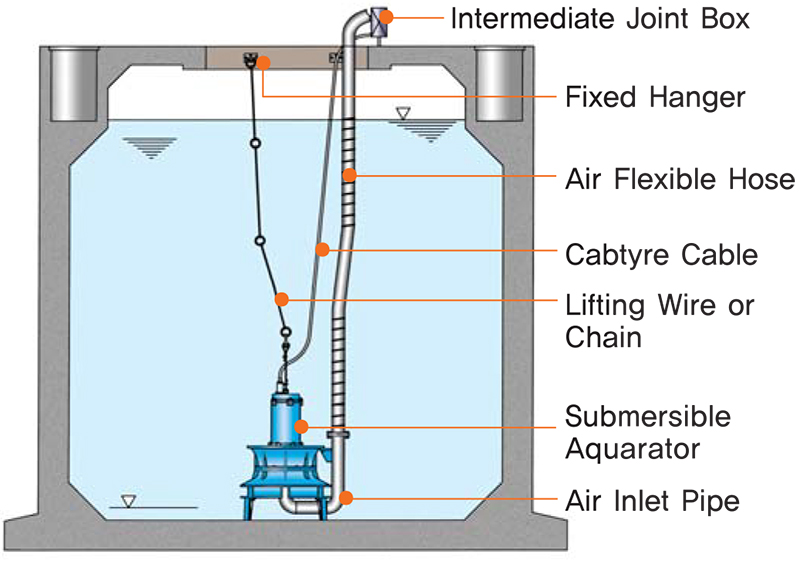

Types of Installations

Flange Connection Type with Flexible Hose

Auto-Setter Type